Over the last 30 years, the average grade of mined Australian ore bodies has halved, while the waste removed to access the minerals has more than doubled.1 This has led to a 70% increase in energy consumption across mining operations.2 Energy costs currently constitute as much as 15% of total mining and mineral processing input costs.3Energy consumption and intensity in mining and mineral processing is rising at around 6% per annum.4 5

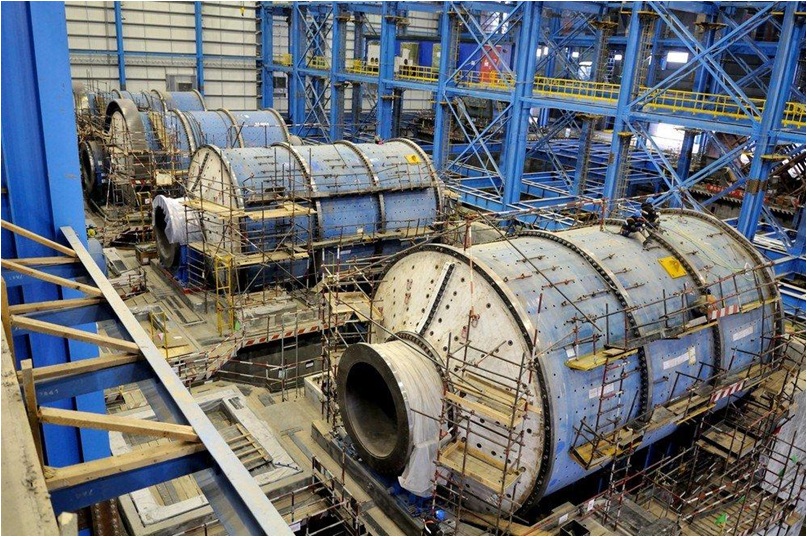

Due to falling ore body concentrations, investment in energy efficiency opportunities will be increasingly important in managing operational costs. There is significant potential to reduce energy costs through an integrated approach to energy efficiency investment. Applying energy efficiency strategies to comminution, the largest area of energy usage, usually offers the best scope for the largest energy and cost savings. Energy is also used in blasting, drilling, dewatering and transporting of mineral ores away from the site. Other significant opportunities for energy savings exist in the areas of froth flotation separation, materials movement and ventilation6 .

Recent Australian studies also suggest that energy savings per tonne of up to 50% below business as usual are practically feasible in the design of new mining and mineral processing developments.7

For more on this, visit the EEX web site: http://eex.gov.au/industry-sectors/mining/#fn-166-1