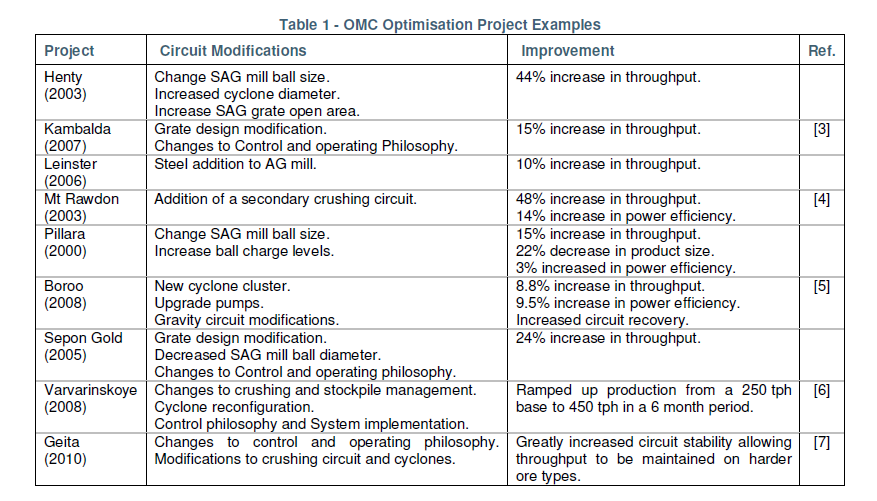

12 case studies show sustained improvement of 15% - 48% throughput over last 10 years at sites including Mt Rawdon, Henty, Kambalda, Sepon Gold and more, reports Orway Mineral Consultants.

Table 1 below is taken from Orway Mineral Consultants (WA) Pty Ltd white paper recently published. It provides examples of optimisation projects undertaken by OMC.

Optimisation is a critical process for maximising the profitability of all metallurgical facilities within the constraints of the project. As Figure 1 shows, comminution is generally the most power intensive process and generally consumes in excess of 50% of total site power. In the US mining industry, 40% of all energy consumption is estimated to be attributed to grinding, inclusive of mining (drilling, blasting, hauling) and processing [1]. Grinding power alone can account for around 20% of direct operating costs in a typical gold plant, inclusive of salaries, wages, fuel, reagents, wear parts, and maintenance [2]. These percentages can be higher for ore types requiring high power input during comminution.