PMS, Hamburg, has announced the release of a highly innovative impact crusher, the VeRo‐Liberator®, which operates in the 100 t/h materials throughput class of complex and inhomogeneous hard materials.

The VeRo‐Liberator® is suitable for the comminution of ores, smelter slags, waste incinerator slags, concrete and numerous other complexly intergrown materials. The technical key advantages are very low energy consumption, an unparalleled high degree of particle liberation and fracturing specifically along particle boundaries, and a particle size reduction from 100‐120 mm diameter input to typically >90% less than 500 micron diameter in a single pass. The Ve Ro‐Liberator® achieves this unusual performance by featuring a vertical, cylindrical axle‐in‐axle system. Each axle‐system is equipped with numerous hammer tools that have a radius of around 100cm. These tools rotate on several levels against each other in a clockwise and anti‐clockwise way at high and variable speeds, thus inflicting extremely high impact forces onto the material. Additionally, the Ve Ro‐Liberator® has a particularly low operating noise level and is maintenance‐friendly due to its modular construction.

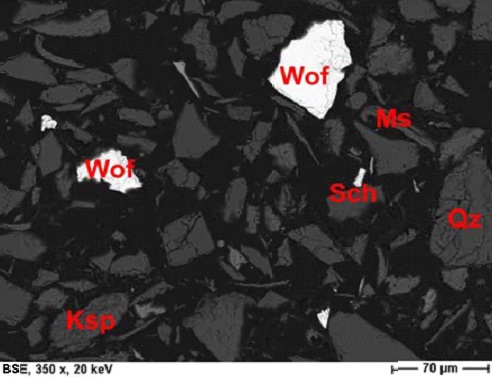

Extensive test runs have been performed on numerous ores and slags from various mines and smelters from all over the world. The comminution results have been investigated and documented by an independent university research institution and comprehensive fact sheets on the results are available upon request on all treated materials. The petrological and rock mechanical research has shown that the unusually high degree of fracturing, separation and thus liberation preferentially along particle boundaries results from a high‐velocity shock wave inflicted by the hammer tools. The various particles react according to their specific mineral properties, i.e. individual compressibility and elasticity moduli. This in turn leads to the favorable fracture formation along particle boundaries, rather than across particle boundaries, which tends to cause incomplete particle liberation in traditional comminution systems.

Test runs on specific materials from interested potential customers can be arranged on request. For further information and contact details see www.veroliberator.de

[caption id="attachment_4416" align="aligncenter" width="538"] The VeRo‐Liberator fitted with a standard feeding system in the foreground.[/caption]

The VeRo‐Liberator fitted with a standard feeding system in the foreground.[/caption]

Low‐grade tungsten‐ore from Wolfram Camp Mine, Queensland, showing complete intergranular particle liberation after single‐pass comminution by the VeRo‐Liberator®

Preprint of short technical information article in “WORLD OF MINING” published by GDMB, Goslar