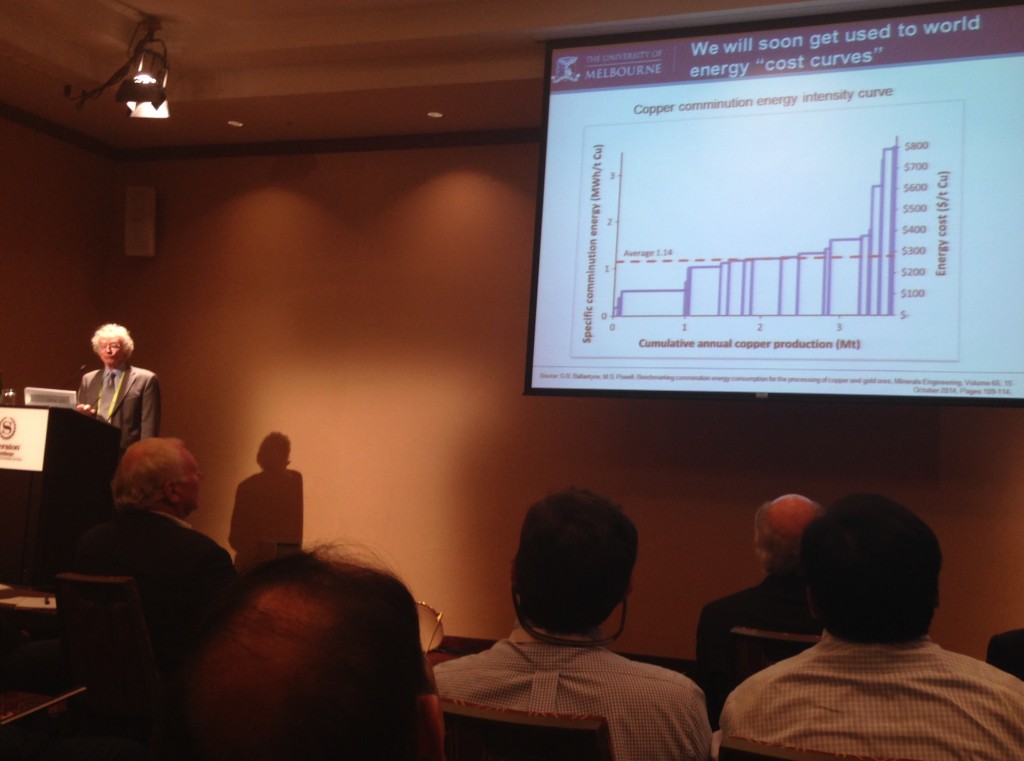

[vc_row][vc_column][vc_column_text]The recent IMPC Sustainability Symposium was co-chaired by Prof Robin Batterham, who also delivered a session paper titled "Progress towards the Sustainable Mine". It was exciting to see Prof Batterham reference key research by Dr Grant Ballantyne, a keynote presenter at the CEEC 2014 workshop. As you can see from the photo taken at the session, Prof Batterham is suggesting energy cost curves will soon be a well recognized measure of performance.

Those of you who attended the AusIMM Mill operator's conference in Townsville in September 2014 will be familiar with Dr Grant Ballantyne's paper presented at that event. Ballantyne's paper is based on a comprehensive Australia- wide survey of comminution energy consumption at copper and gold mines presented by the authors at the 11th AusiMM Mill Operators' Conference 2012. The database has been extended to include major overseas mines and used to benchmark comminution energy consumption across the industry. The mines included in this study now represent 15 and 24 per cent of the total global gold and copper production respectively, and almost all Australian production. The comminution energy intensity per unit of saleable metal has been presented in a graphical form similar to a cost curve used in economics. The graphical method has been developed to assess the competitive advantage that can be achieved by reducing comminution energy intensity.

This bench-marking tool has been applied to three published case studies to assess its applicability. The first case study indicated that a large reduction in size-specific energy (kWh/t -75 µm) was achievable by converting standard semi-autogenous and ball mill circuits to include high pressure grinding roll and stirred mills. The second case study investigated the metal-specific energy reduction historically achieved by Bougainville with the addition of a pre-concentration screening plant. The final case study was conducted by Barrick Gold Corporation and involved incremental efficiency upgrades at three of its gold mines: Cortez, Cowal and Mara North. The application of the benchmarking tool to each of these case studies successfully demonstrated the scale and competitive advantage that was achieved by reducing energy intensity.

Prof Robin Batterham joined the Melbourne School of Engineering as Kernot Professor in the Department of Chemical and Biomolecular Engineering in 2010. Professor Batterham is devoted to furthering energy research in the University and is deeply involved with the Melbourne Energy Institute. He brings enormous expertise and experience to the School, building on his long and very distinguished career in industry and government, and is the immediate past President of the Academy of Technological Sciences and Engineering (2007-2012).

[/vc_column_text][/vc_column][/vc_row]